Product Development

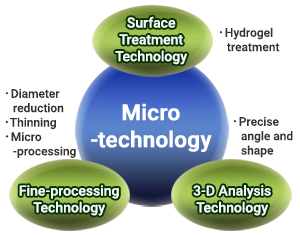

Core Technology

Infinite Possibilities of Microtechnology

“Creating from nothing”

We develop new and original products out of quick inspiration using both new and core technologies to fulfill the needs of Doctors.

Our own core technologies are used in creating the medical devices that we serve.

For example, intervention that cannot be performed without guidewires and catheters have surfaces of hydrophilic factors as well as specially processed technologies embedded in them.

Microtechnology is utilized for seeking the targeted lesion by the peripheral vessel or by the gastrointestinal tract.

Stents that require accuracy in angles and shapes, plates that are used for neurosurgery utilize a 3-D analysis technology in which it leads to a high degree of microtechnology and forming of shapes.

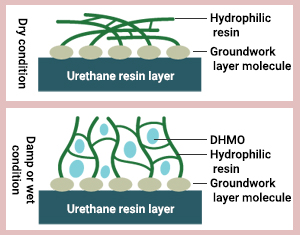

Surface Treatment Technology

The picture on the right shows a pattern diagram of a surface applied with hydrophilicity.

Immediate lubricity appears when moistened with water.

Catheters and guidewires that have contact with blood and body fluids are processed with this hydrophilic factor.

Inserting foreign matters lead to a formation of thrombus but with this hydrophilic factor, thrombosis can be prevented.

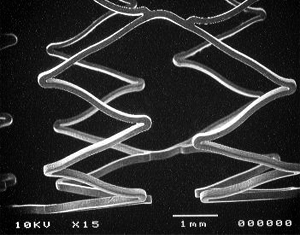

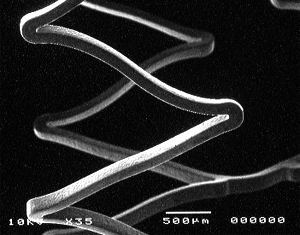

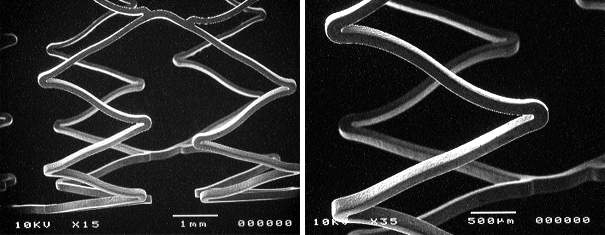

Fine-processing Technology

Fine-processing Technology

Stents are implanted in areas where the vessels and gastrointestinal tracts are narrow with strictures so that the tubes are dilated to maintain its original shape and the flow of blood and digestive juices are near to being normal.

Designing and fine processing is necessary for each intended purpose.

The enlarged picture on the right was taken under a microscope and it shows struts of a stent that is made of Ti-Ni super elastic material.

The stent is manufactured by performing a laser cut on a φ2mm Ti-Ni made pipe according to its requested patterns.

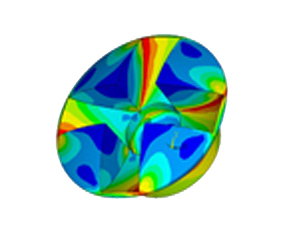

3-D Analysis Technology

3-D Analysis Technology

This photo shows screws that are used with neurosurgical plates.

It represents the results of the Finite Element Analysis (FEA) of the screws.

The FEA uses a numerical modeling to given load (power or pressure) structure that is applied and foresees the influence.

The shape was optimized by observing the influence on the screwhead when screwed using this method.